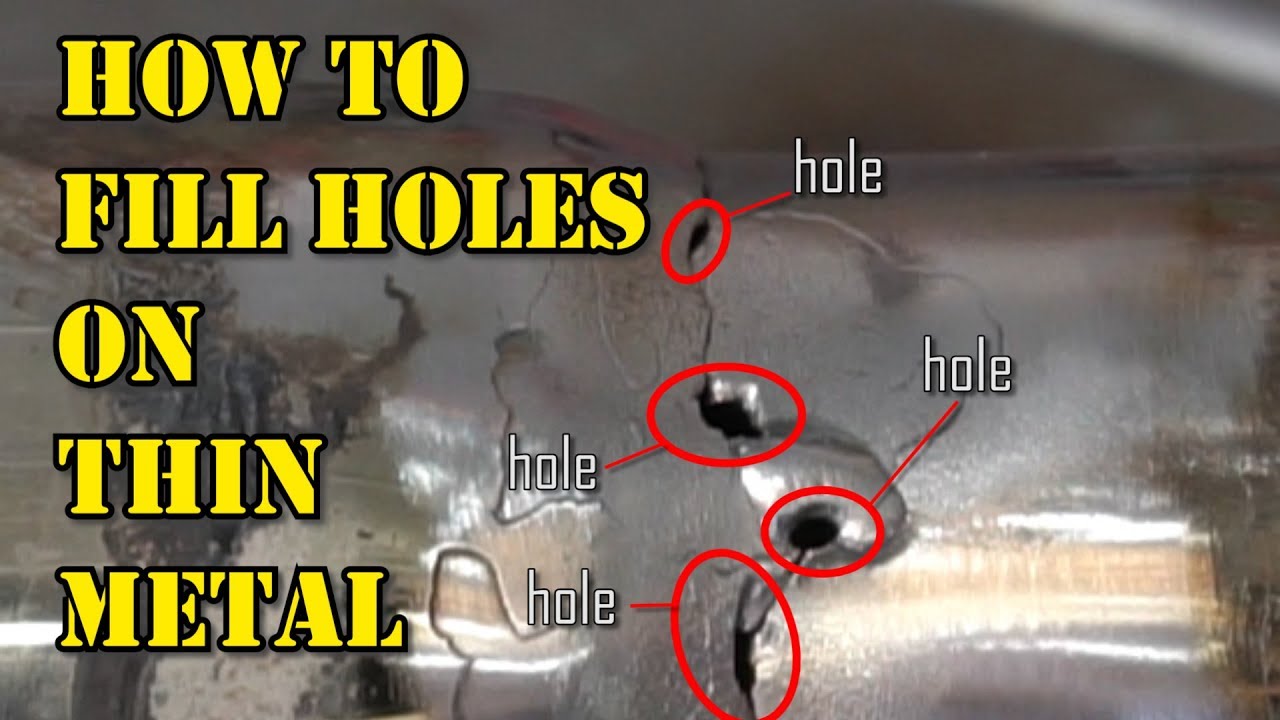

Fill Sheet Metal Holes

Repairs cracks or porosity leaks in cast metal parts.

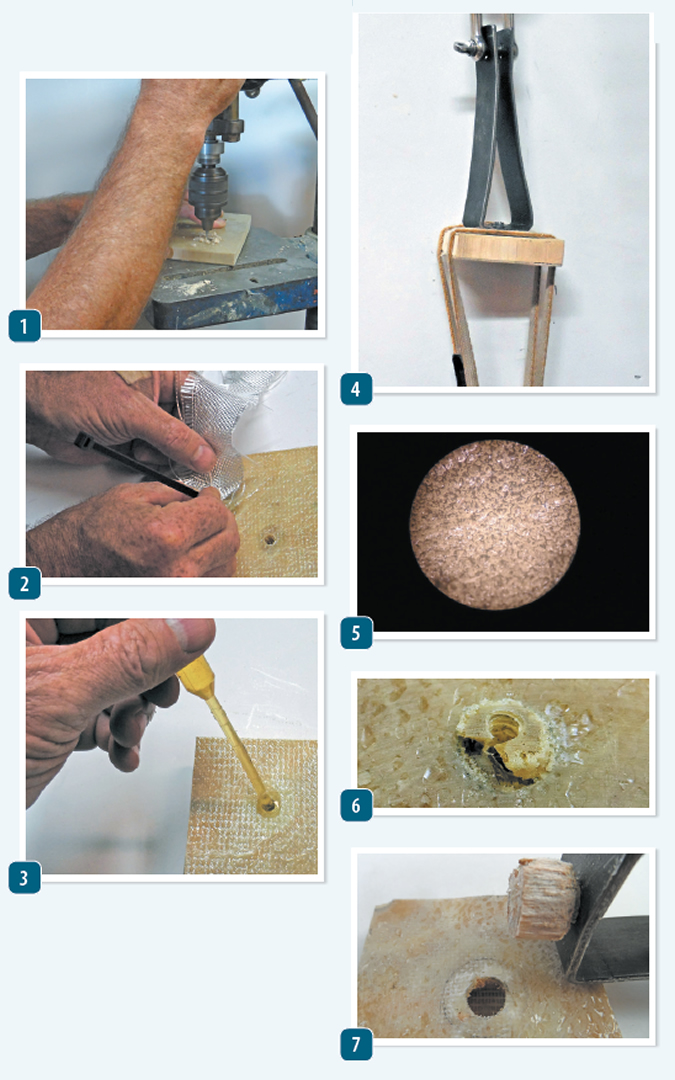

Fill sheet metal holes. Fills small holes cracks and perforations. Liquid metal filler will dry in 3 to 4 hours. The wooden bread layers of the sandwich keep the sheet metal flat and prevent the drill bit from wandering as it bores through the sheet metal. For filling deep holes apply liquid metal filler.

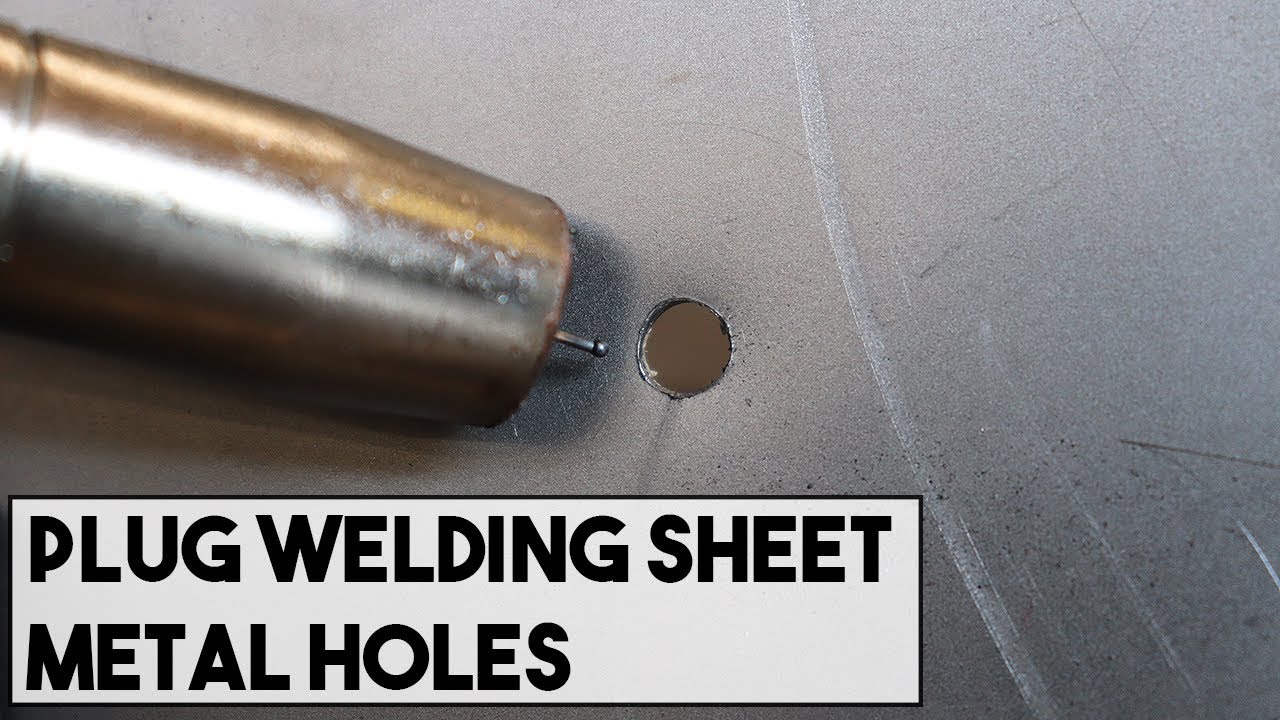

I then used the templates to trace out the patch panels on some sheet metal. Works on metal wood and concrete. Allow each layer to dry before adding the next. How to fill trim holes with a welder.

Easy to use filler can be drilled filed sanded and painted. The process of welding to fill trim holes is done with stitch welding. For these types of holes i start by cleaning the area around the hole with an angle grinder and flap disc. Use acetone or nail polish remover to clean up excess liquid metal filler.

If you know how to weld take advantage of your tools for a longer lasting repair. Forms a long lasting metal tough bond. Sheet metal repairs should always be made with weld thru coating on the seams before the welds are made. Holes in thin metal can be filled with plugs.

After slicing the patches out with a cutoff wheel next came the bending hammer and dolly session until the patches matched the holes and fit snug and flush into the flanged seat. The easiest holes to fill are small holes about the diameter of a pen or smaller. Whether you re dealing with a small piece of sheet metal or something valuable like a car you can fix it. Apply liquid metal filler straight from the tube.

I used a piece of pvc pipe a vice mount miniature metal break and body hammer kit. Did you want to learn how to work around that and deliver a solid re. A long bead does two things on thin metal puts a lot of heat into the metal and tends to burn through the metal. Simply sandwich the sheet metal between two pieces of wood and clamp everything down on a table or workbench.

When filling thick sheet metal like that i let the copper plug stay a little proud on the show side and dressed it down the back side i filled with polyester filler bondo and as it deserves repeating i can not over emphasize the importance of cleaning the sheet metal thoroughly before soldering. For clean precise holes in thin sheet metal make a wood sandwich. Have you ever welded something so thin and worn out that all you do is blow holes in it. If desired use a wet putty knife or spatula to smooth out the repair.

Perhaps a simple rivet or sheet metal screw can be secured in the hole. Sheet metal on the body of cars and trucks is pretty thin usually 18 22 gauge. If the hole needs to contain a liquid a rubber washer can go on the sheet metal screw to render it water tight. By filling in holes you stop rust in its tracks and ensure the metal lasts longer.