Fibre Cement Roofing Sheets Manufacturing Process

Widely used within industrial or agricultural buildings these sheets are well known for their durability and longevity.

Fibre cement roofing sheets manufacturing process. Pros and cons of fiber cement roofing. Fibre cement roof sheets also known as fibre cement board or cement fibre roof sheets can be used for a variety of domestic industrial and agricultural uses. Hence we forward integrated into utilising our own quality cement certified by son standards organization of nigeria to manufacture top rite fibre cement roofing sheets boards to cater to the growing requirement of newly built houses tin roofing replacement market as well as wood. The research work is relevant to the current study in several ways.

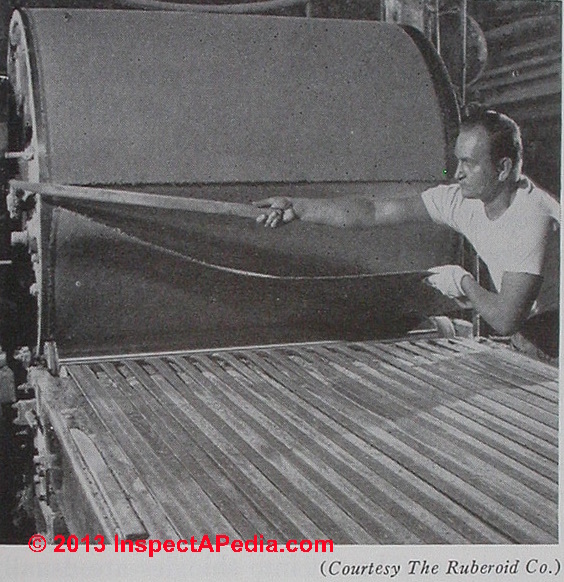

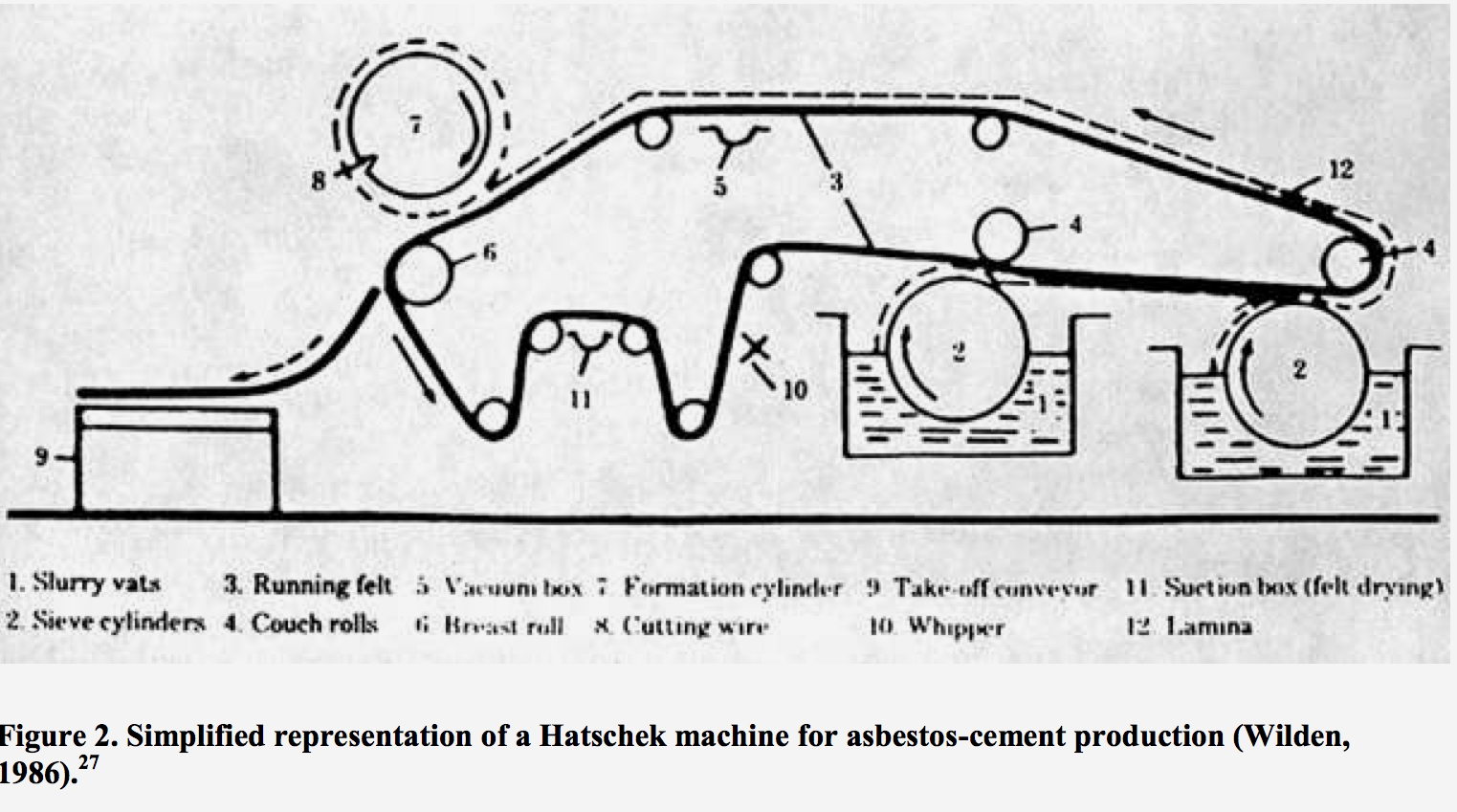

Performance and cost of production in fiber cement sheet production industries 6. Fibre cement sheets have been used for decades in roofing. The basic methodology of producing the cement asbestos has changed little in the last 100 years by terry dash and tim gane step5 1. Fibre cement roofing is a perfect full replacement for the old banned asbestos roofing it also serves as a safe and easy method of repair for the existing roof and is compatible with the 3 inch and big 6 profile fibre cement roofing is popular for livestock buildings because.

This type of roofing material s inventor got the first patent in 1901. Cement and reinforcing fibre originally asbestos in a 10 1 ratio are mixed with water to form a thick slurry. Wikimedia commons has media related to fibre cement. While fiber cement roofing is relatively cheap there are a number of pros and cons with this material which you should.

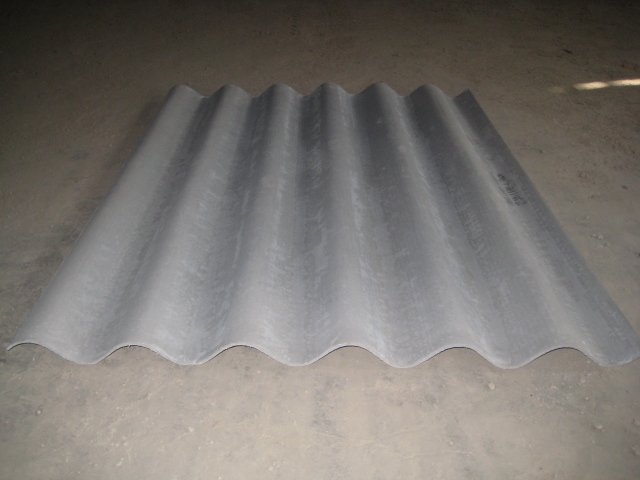

Fibre cement sheets provide excel lent fire protection characteristics are suitable for use in wet rooms and have an impressively high level of stability in comparison to gypsum boards. Coir fibre reinforcement and application in polymers composite 8. One common use is in fiber cement siding on buildings. The sheets are corrugated or pro duced in the form of small slates.

At pil the spot light is on being an environmentally conscious organization. They re made from an environmentally friendly fibre. Big names brands such as cembrit and marley eternit make up our comprehensive range of fibre cement roof sheeting so you can choose the perfect fit for your project. We only supply fibre cement products that are produced in the uk by the uk s prestigious manufacturers marley eternit.

Recent studies on fibre cement roofing manufacture include. Fibre cement is a composite building and construction material used mainly in roofing and facade products because of its strength and durability. Fiber cement roofing uses panels made from fiber cement which is where the basic cement formula is reinforced with fiber such as cardboard and similar items these panels can then be turned into either roofing slates or sheets which are shaped to resemble corrugated iron. Small quantities of other chemicals eg cellulose is added to aid the manufacture process.

Fibre cement recycling from the grave back to the cradle 7.